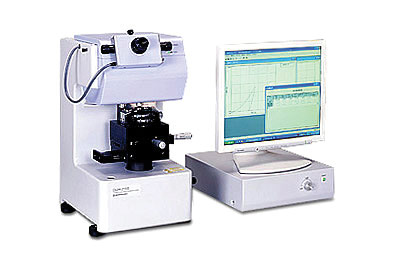

DUH-211/DUH-211S

A new evaluation system for measuring the material strength of micro regions, such as semiconductors, LSI, ceramics, hard disks, vapour deposited films, and thin coating layers, not addressed by previous hardness testers. It can also be used to evaluate the hardness of plastics and rubbers.

This instrument uniquely measures dynamic indentation depth, not the indentation after the test. This in turn permits measurement of very thin films and surface (treatment) layers that are impossible to measure with conventional methods. Additionally, this same method supplies the data needed to calculate elastic modulus on the test specimens.

Features

- Evaluation of Hardness and Material Parameters in Accordance with Standards (ISO 14577-1 Annex A)

Measure the behavior of a specimen as an indenter is pressed into it and evaluate the hardness, elastic modulus, and amount of work done during indentation, in compliance with and ISO 14577-1 (instrumented indentation test for hardness) Annex A. - Highly Precise Evaluation of Elastic Modulus

Perform highly precise evaluation of the elastic modulus, using correction based on instrument rigidity and the shape of the intender tip*1. - Low Test Force with Measurement Resolution of 0.196 μN

Control the test force using a high resolution of 0.196 μN. This allows measurement of material strength properties in micro regions and in the outermost surfaces of specimens. - Ultra-Wide Test Force Range of 0.1 to 1,961 mN

Use a wide test range of 0.1 to 1,961 mN for measurement, and test a variety of industrial materials, including rubber, plastics, and ceramics. - High-Precision Measurement of Indentation Depth

No need to measure the actual indentation. Specimen indentation depth can be measured in units of 0.0001 μm for depths up to 10 μm. - Supports a Wide Range of Testing Methods

Record the relationship between the test force and the indentation depth. Test both the unload and load processes. Use the DUH-211S to perform cyclic load-unload tests and step load-unload tests. - Supports Vickers Hardness Test

function to measure the length of diagonals is provided as a standard feature. This function allows you to measure the hardness that corresponds only to plastic deformation, Vickers hardness, and Knoop hardness. (A Vickers indenter and Knoop indenter are available as options.) Maximum microscope magnification is 500× (1000× is available as an option)

*1 Indenter tip shape correction is only available for the 115-degree triangular pyramid indenter. Shape correction is not available for other indenters.

Measurement Principle

Electromagnetic force is used to press an indenter (standard type: 115° triangular pyramid) against a specimen. Pressing force is increased at a constant rate, from 0 to the preset test force. Indentation depth is automatically measured as the indenter is pressed against the specimen. This allows dynamic measurement of changes that occur in the specimen's resistance to deformation during the indentation process, and obtains a wide variety of data. During indentation the DUH-211/211S measures dynamic hardness and evaluates the hardness that corresponds to both plastic and elastic deformation. Also, if the indentation size is large enough to be observed with a microscope, hardness can be calculated using just the plastic deformation, by measuring the diagonal length of the indentation.

Expressions for Dynamic Hardness

Expressions for Dynamic Hardness

- 115° triangular pyramid indenter (standard)

DHT115 = 3.8584 × F / h2 - 100° triangular pyramid indenter (option)

DHT100 = 15.018 × F / h2 - Vickers indenter (option)

DHV = 3.8584 × F / h2 - Knoop indenter (option)

DHK = 1.5583 × F / h2

Even though the theoretical unit for these hardness expressions is kgf/mm2, it is normally not used.

Expressions for Martens Hardness (ISO 14577-1 Annex A)

- 115° triangular pyramid indenter (standard)

HM115 = 1000 F / 26.43 × h2 [N/mm2] - Vickers indenter (option)

HMV = 1000 F / 26.43 × h2 [N/mm2]

Hardness Expressions Based on Diagonal Length

1. 115° triangular pyramid indenter (standard)

HT115 = 160.07 × F / d2

2. 100° triangular pyramid indenter (option)

HT100 = 121.53 × F / d2

3. Vickers indenter (option)

HV = 189.10 × F / d2

4. Knoop indenter (option)

HK = 1451.1 × F / d2

DUH-211/DUH-211S Applications

Metal Materials : Capable of measuring micro-structure constituent components within a sample, not just overall hardness.

Plastics : Measurement of materials exhibiting high light absorption, which is difficult for conventional methods, is easily performed on the DUH-211 series.

Rubbers and Elastomers : Rubber hardness has traditionally been measured under a set of fixed conditions according to JIS K6301/ISO7619 using a rubber hardness tester. Now, the DUH-211 permits measurement of this same amterial under various different sets of conditions. Additionally, this instrument also permits hardness measurement of the surface layers alone, thus providing useful information for the study of surface deterioration.

Glasses and Ceramics : The DUH is capable of measuring brittle samples, such as glass and ceramics, either with or without forming cracks.

Thin Films : Measuring the strength of film coatings produced by chemical vapour deposition (CVD), physical vapour deposition (PVD), or surface layers treated by ion implantation, is important for improving film production techniques. Since the DUH-211 is able to measure using ultra-low loads, it is ideal for this application.

Fibers : The DUH-211 provides useful information for strength evaluation testing on glass fibers, carbon fibers, whiskers, fibers made of other composite materials, and optical fibers.

Electronic Parts such as IC and LSI : Hardness is an important factor for the evaluation of reliability of LSI and other electronic elements. The DUH-211 permits easy hardness testing of the desired parts of the pattern on an IC or LSI.

Particulate Matter : Use of the optional flat-tip indenter provides easy measurement of particle proof stress. This data is useful for improvement of the pretreatment technique or fine particles.

DUH-211/DUH-211S Specifications